high quality vertical sump pump drawing

Latest articles

Choosing the right , slurry pump, for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the , slurry pump supplier, will share them with you.+

high quality vertical sump pump drawing...

high quality vertical sump pump drawing 【high quality vertical sump pump drawing】

Read MoreIn a word, the wear-resistant properties of the slurry pumps are stronger, and the ability to convey particles is also stronger. Generally, the capacity of the slurry pump is larger than the mud pump, which is mainly used for coal and metal ore washing. The mud pumps are more suitable for abrasive slurry is not very strong.

high quality vertical sump pump drawing...

high quality vertical sump pump drawing 【high quality vertical sump pump drawing】

Read MorePumping slurry can cause excessive wear and tear on the pump and its components as the mud can clog the suction and discharge lines.

high quality vertical sump pump drawing...

high quality vertical sump pump drawing 【high quality vertical sump pump drawing】

Read MoreSlurry Pump

high quality vertical sump pump drawing...

high quality vertical sump pump drawing 【high quality vertical sump pump drawing】

Read MoreThere are several types of slurry pumps, the most common being: centrifugal and volumetric pumps.

high quality vertical sump pump drawing...

high quality vertical sump pump drawing 【high quality vertical sump pump drawing】

Read Moretarget=_blank title=Rubber Liner Pumps>Rubber liner pumps have been used for nearly a century to protect plants and equipment from wear and retain their place as the wear material of choice for pumping and separating fine-grained slurries.

high quality vertical sump pump drawing...

high quality vertical sump pump drawing 【high quality vertical sump pump drawing】

Read MoreWZ series slurry pumps are new type wear resistant & corrosion resistant slurry pump for the complexity and specificity of coal, power plant, metallurgy, chemical, building materials and other industries.

high quality vertical sump pump drawing...

high quality vertical sump pump drawing 【high quality vertical sump pump drawing】

Read MoreSlurry pumps are mainly used in industrials of mining, metallurgy, dredge, power, coal and other solid slurry transport.

high quality vertical sump pump drawing...

high quality vertical sump pump drawing 【high quality vertical sump pump drawing】

Read More>Slurry Pump

high quality vertical sump pump drawing...

high quality vertical sump pump drawing 【high quality vertical sump pump drawing】

Read MoreAIER will always strive to be your common sense slurry pump and parts supplier in a complex world!

high quality vertical sump pump drawing...

high quality vertical sump pump drawing 【high quality vertical sump pump drawing】

Read More

Popular articles

- >Slurry Pump vs Mud Pump

- What is a dredging pump?

- 3.Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear and tear caused by abrasive slurries. Slurry pumps are typically larger in size compared to low viscosity liquid pumps and often require more horsepower to operate due to their lower efficiency. Bearings and shafts must also be more robust and durable.

- Because of these requirements, slurry pumps are usually larger than their clear liquid counterparts. In addition, it usually sacrifices efficiency, i.e. maximum efficiency and efficiency throughout its operating range, in exchange for the ability to achieve good operation in these challenging services.

- When flushing is required, the >slurry pump supplier recommends the API Option 32 sealed pipe arrangement as it is more suitable for services containing solids or contaminants that could damage the seal faces if recirculated in the flushing medium.

- Process speed doesn’t have anything to do with choosing slurry pump impeller, but it does have an effect on the life of slurry pump impeller. It is important to find the sweet spot that allows the slurry pump to run as slow as possible, but fast enough to keep solids from settling and clogging. If pumping too fast, the slurry can quickly erode the impeller due to its abrasive nature. This is why it is important to select a larger impeller if possible.

Latest articles

-

2.Pumping slurries poses several challenges and problems, but with proper engineering and equipment selection you can experience many years of worry-free operation. It's important to work with a qualified engineer when selecting a slurry pump because slurries can wreak havoc on a pump if not properly selected.

-

target=_blank>Slurry Pump

-

It is also important to consider the chemical compatibility of the slurry with any elastomers in the pump. Once the nature of the slurry and the components of the different types of pumps have been addressed, you can select potential candidate slurry pumps for the application.

-

A dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

-

>Slurry Pump

-

Firstly, analysing your duty helps us to determine whether you are using the type and size of pump best suited to your needs. Cavitation can occur due to surges; a very effective way to solve this problem is to install a choke on the pump head to increase the pressure on the casing, which then absorbs the surge, or to add a choke to the output to reduce the surge.

Links

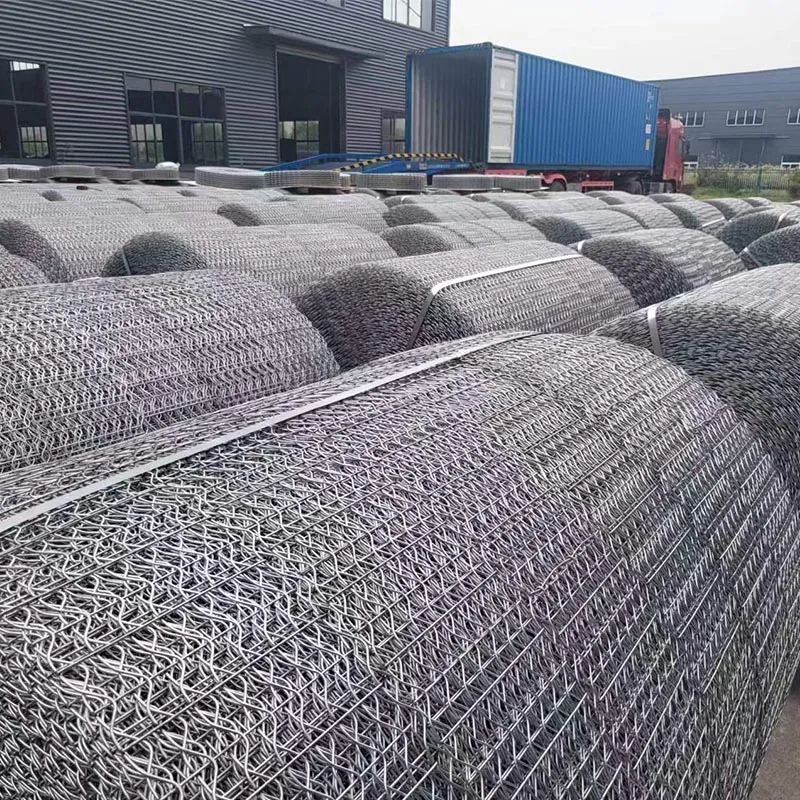

Elliptical Motion Screens: Elliptical motion screens combine linear and circular vibration patterns, offering versatility and efficient separation for various materials.

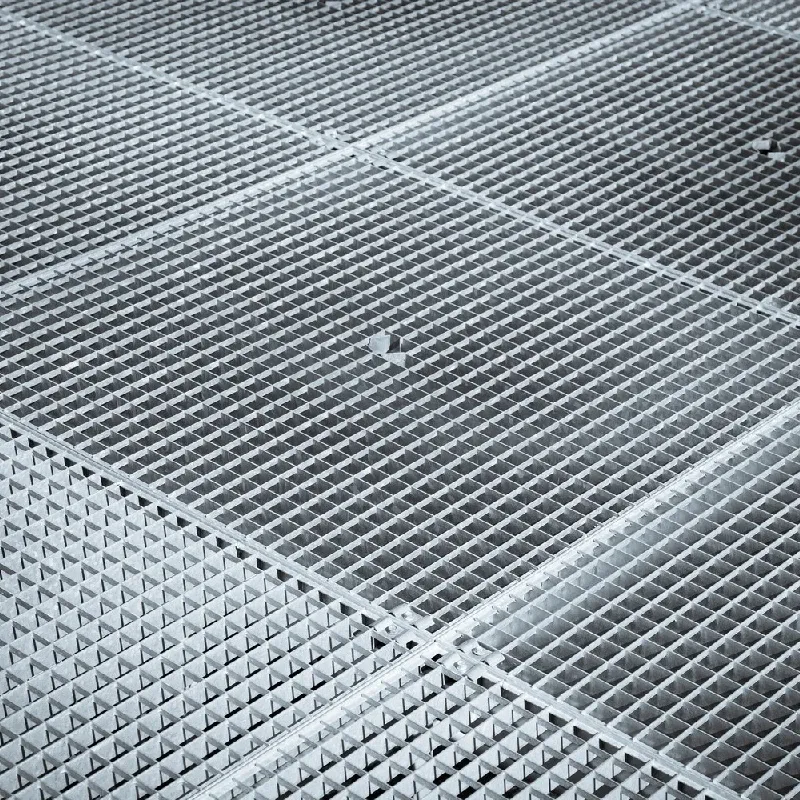

Furthermore, walkway grates contribute to sustainability efforts in urban design. By allowing water to permeate the ground, they promote natural aquifer replenishment and support the health of the surrounding ecosystem. These grates can also reduce the heat island effect commonly found in urban areas, as they help maintain cooler temperatures by allowing moisture to evaporate and regulate surrounding air temperatures.

The Importance of Shaker Screens in Oil and Gas Operations

Heavy Duty Steel Grating En Solid Løsning til Industrielle Behov

Choosing the Right Drain Cover